SWR PIPES & FITTINGS

SOIL WASTE & DRAINAGE SYSTEAM

SWR pipes and fittings are components used in plumbing systems, particularly for the disposal of soil, waste, and rainwater in buildings. “SWR” stands for Soil, Waste, and Rainwater. These pipes and fittings are essential for maintaining proper sanitation and drainage within a structure

Superior Quality Standards And Wide Range

Free From Chemical And Corrison Resistance

Light In Weight,Thus Reducing Transportation

Extra Stronger And Longer Lasting

Quick And Productive Removal Of Waste Without Leakages

For Domestic And Commericial Purposes

SWR PIPES TYPE

Conforming to IS:13592:2013

SWR PIPE FITTINGS

Conforming to IS:14735:1999

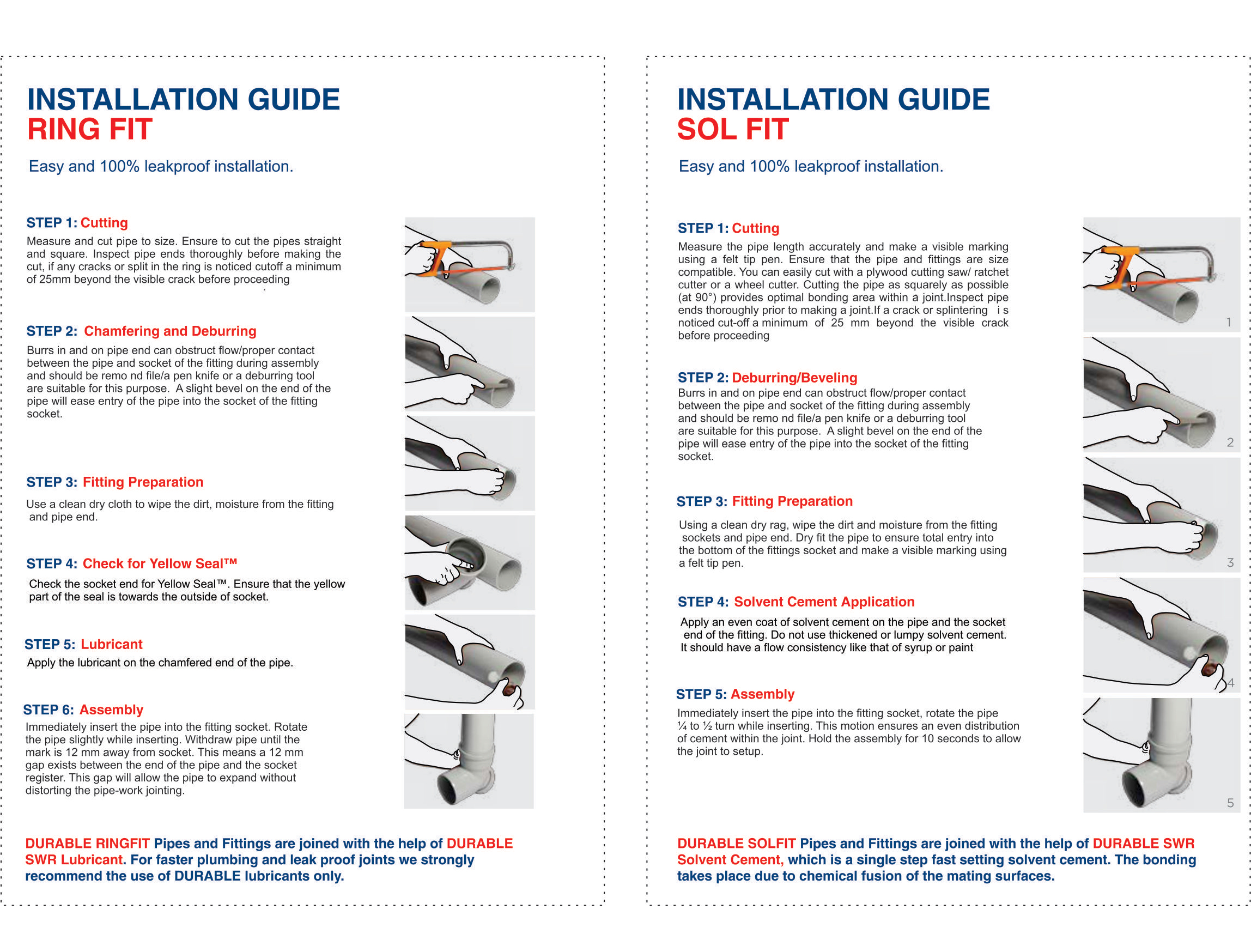

RING FIT

SOL FIT

MATERIAL

Material: SWR pipes are commonly made from UPVC (Unplasticized Polyvinyl Chloride) or PVC-U (Polyvinyl Chloride – Unplasticized). These materials offer durability, corrosion resistance, and the ability to withstand the conditions associated with soil and waste disposal.

Types of Fittings:

Bends: Used to change the direction of the pipe.

Tees: Allow the branching of pipes in different directions.

Reducers: Used to connect pipes of different diameters.

Traps: Prevent foul odors and gases from entering the building by maintaining a water seal.

Vent Caps: Allow the release of gases and prevent the entry of debris into the system.

Accessories: Various fittings like couplers, sockets, and brackets facilitate the installation and maintenance of the system.

Jointing Methods: SWR pipes are typically joined using solvent cement. This involves applying a PVC solvent cement to the pipe and fitting surfaces, which, when dried, creates a strong and watertight bond.

Corrosion Resistance: The materials used in SWR pipes and fittings are resistant to corrosion and chemical reactions, ensuring a long lifespan for the plumbing system.

Smooth Interior Surface: SWR pipes usually have a smooth inner surface, which helps maintain a steady flow of waste and prevents the accumulation of debris or sediment.

Conformity to Standards: SWR pipes and fittings should conform to relevant standards and codes to ensure their quality, performance, and compliance with local regulations.

Color Coding: SWR pipes and fittings are often color-coded for easy identification. For example, gray or dark colors are commonly used for these pipes.